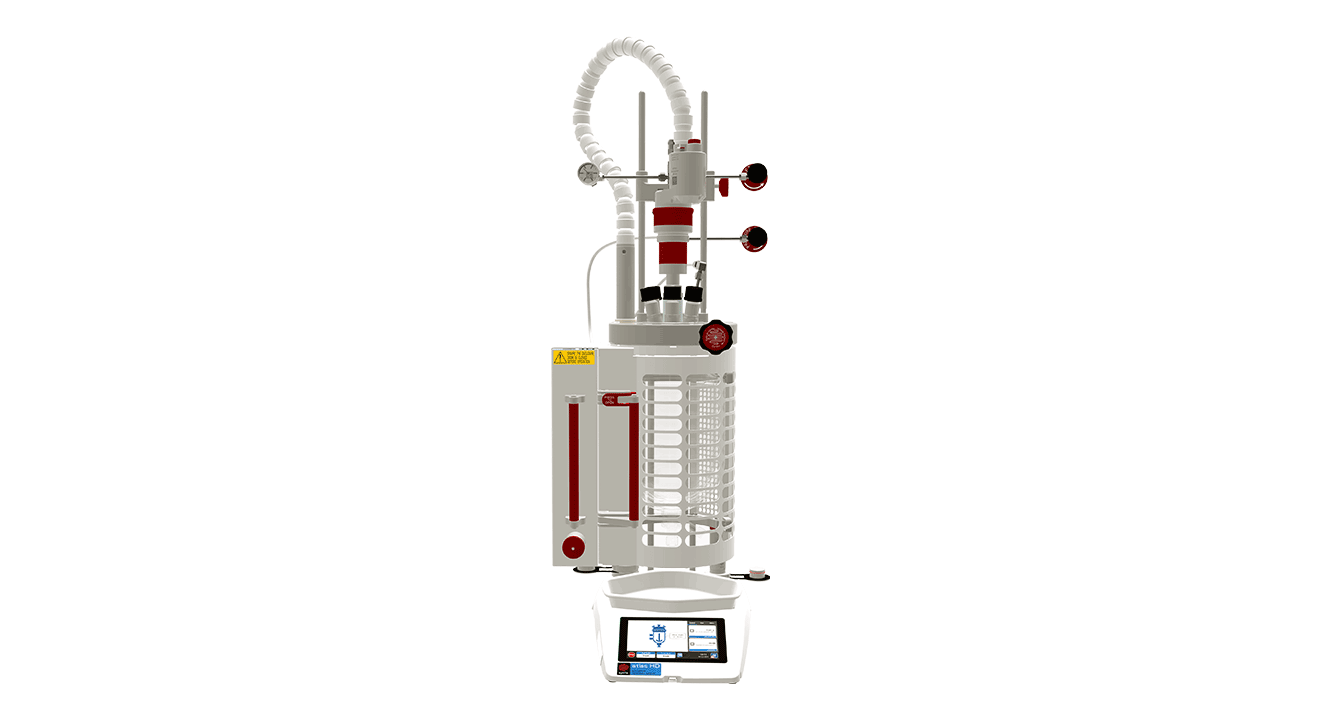

Atlas high pressure reactor at a glance

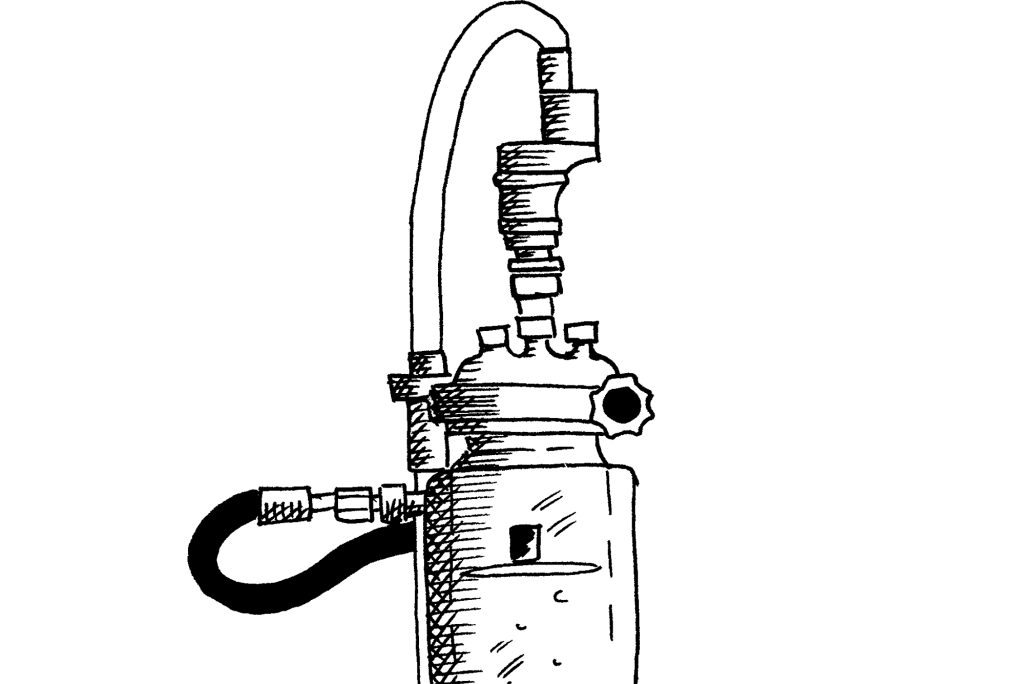

The Atlas HD 3 Bar Pressure System is designed for chemical processes that require a wide range of operating pressures, such as hydrogenations, carbonylations, or high-vacuum applications.

The basic system allows automatic temperature control from -80 °C to +200 °C, stirrer control of up to 800 RPM, and pressure sensing.

- Reactor volumes from 100 mL to 3 L

- Automatic temperature control (-80 °C to +200 °C)

- Stirrer control (up to 800 RPM)

- Reactor volumes from 100 mL to 3 L

- Automatic temperature control (-80 °C to +200 °C)

- Stirrer control (up to 800 RPM)

1. Powerful control

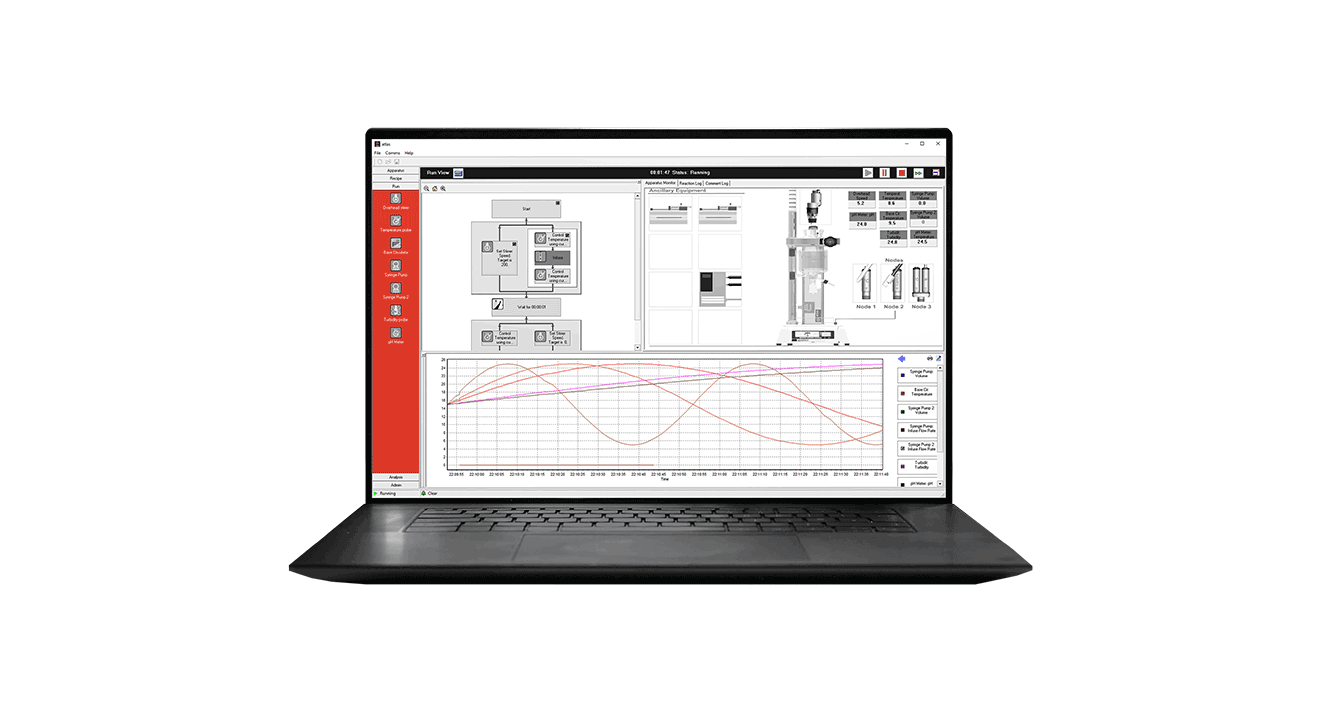

The high pressure reactor can be controlled using the touchscreen base or the Atlas PC Software, providing a graphical display of pressures, temperatures, etc. Mass flow meters and controllers can also be integrated.

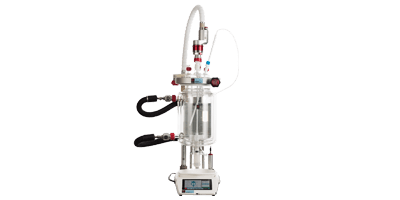

2. Wide Vessel Range with Seamless Interchangeability

Seamlessly drain the oil from your jacketed reactor using the Oil Drain Unit and change reactors in minutes. The system has a wide range of vessels, all rated to 3 bar, including 100 mL, 250 mL, 500 mL, 1 L, 2 L or 3 L, with or without a vacuum jacket. The tool-free vessel clamp supports the reactors to ensure safe vessel change without any fuss or spillages.

3. Safe and convenient

The Atlas HD 3 Bar Pressure System combines all the great user features of Atlas with all the safety features you would expect from a pressure system. It is equipped with a factory-set maximum pressure burst disc and pressure relief valve to ensure the glass reactor can never see an unexpected pressure rise. The safety enclosure has been designed to provide that extra peace of mind and to ensure a very safe laboratory.

4. Precise temperature control

The system has a wide temperature range from -80 to +200 °C with accurate thermal control using either the touchscreen base or PC control software. Simply connect a compatible circulator to the base unit or PC software and precision temperature algorithms will ensure your process performs without issues.

5. Easy to use

Consistent with all the systems in the Atlas range, no tools are required, allowing simple twist-and-click configuration of the apparatus, large displays and intuitive control from the base unit or PC software.

Additionally, integrated filters can be used to separate solid catalysts from the mixture, enhancing the efficiency and purity of processes.

6. Stirred Autoclave Functionality

The system is equipped with an optimized stirrer that ensures thorough mixing of reactants, promoting uniform reaction conditions and improving efficiency and yield. Made from high quality materials, the pressure vessel is designed to withstand corrosive environments and maintain integrity under high pressures.

Safety features such as a factory-set maximum pressure burst disc, pressure relief valves, and a robust sealing system prevent leaks and ensure safe operation under elevated pressures. The stirred autoclave can be easily integrated with other modules and accessories, allowing for customized setups tailored to specific research needs.

What our customers say

We run two Atlas HD 3 Bar Pressure systems in parallel, and can quickly and easily configure the reactors for advanced applications such as calorimetry and crystallization control”

Specifications

| Vessel Volume Range | 50 mL, 100 mL, 250 mL, 500 mL, 1 L, 2 L (DN80), 1 L, 2 L, and 5 L (DN150) |

|---|---|

| Vessel Shapes | Torispherical, Conical, Round Bottom |

| Vessel Profiles | Jacketed, Vacuum Jacketed |

| Other Vessel Types | No (Round bottomed flasks cannot be used with the Atlas HD 3 Bar Pressure System) |

| Temperature Range | -90°C to 250°C (with suitable seal kit) |

| Stirring Options | Scorpion Overhead Stirrer (up to 800rpm/11Ncm torque), High Speed Available, High Torque Available, Optional Heidolph stirrer available |

| Automation | Yes – as standard |

| Modes of Operation | Atlas PC Software, Manual Operation, Click Wheel Control |

| Sensor Options | Temperature, pH, Pressure, Turbidity, In-situ FTIR, Other Sensors Available |

| Pressure Range | 1.78 mbar to 3 Bar |

| Reaction Calorimetry | Ability to Upgrade to Reaction Calorimetry, See Atlas HD Calorimeter |

| Reagent Addition and Sampling | Manual Dosing, Automated Dosing (Volumetric), Automated Dosing (Gravimetric), Sampling of Liquids, Atlas Syringe Pump Range |

Laboratory applications: High-pressure reactor uses

The Atlas HD 3 Bar Pressure System is designed to excel in a variety of pressurized laboratory applications, offering reliable performance. Its robust construction and advanced features make it ideal for:

-

Hydrogenations

Utilize the system’s pressure vessel capabilities to efficiently add hydrogen to organic compounds. The stainless steel construction ensures resistance to corrosion, maintaining the purity of reactions.

-

Reactions under a range of pressure

This system is suitable for high-vacuum conditions. The inert inner surfaces prevent contamination, providing a clean reaction environment.

-

Corrosion testing

The system’s robust glass pressure vessel is perfect for testing the corrosion resistance of materials under high-pressure conditions, ensuring the long-term durability and reliability of products.

-

Homogeneous and heterogeneous catalysis

The advanced control systems and modular design of the Atlas 3 Bar System support both homogeneous and heterogeneous catalysis, providing precise control over conditions.

-

Polymerization Reactions

The system can be used for polymerization reactions, which requires elevated pressures to ensure uniform polymer formation and enhanced material properties.

-

Hydrothermal Synthesis

Ideal for synthesizing advanced materials like zeolites and metal-organic frameworks under high-pressure and high-temperature conditions.

Modules

-

Base units

-

Atlas HD System

The Atlas HD System is the base reactor system on which all Atlas HD systems are built, and can be […]

View module details

-

-

Vessels and Stirrers

-

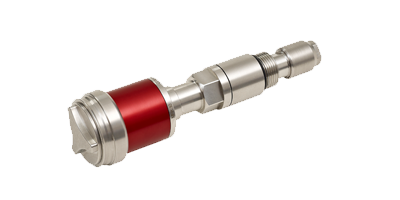

Atlas Scorpion Overhead Stirrer

The Atlas Scorpion Overhead Stirrer is a quick release, high RPM stirrer motor, and coupling. The Scorpion Overhead Stirrer provides […]

View module details -

Stirrer Seal and Guide (Atlas 3 bar System)

The Stirrer Seal and Guide is rated to 3 bar and is designed for use with the Atlas 3 Bar […]

View module details -

Jacketed Vessels (rated to 3 bar)

There is a range of jacketed reactor vessels that are rated to 3 bar and are designed for use with […]

View module details -

Vessel Lid and Safety Manifold (3 bar system)

The Jacketed Vessel Lid and Safety Manifold for the 3 bar system is designed for use with the Jacketed Vessel […]

View module details

-

-

Probes and Nodes

-

Temperature Node and Probe

Easy connection to the Atlas HD base. Our probes are available in different lengths to suit different vessels.

View module details

-

-

Automation

-

Atlas PC Software 1

Atlas Software 1 is an easy-to-use PC based application for control and analysis of experiments. Whole systems including stirrers, circulators, […]

View module details

-

-

Advanced Applications

-

Atlas Jacketed Vessel Clamp (3 Bar System)

The Jacketed Vessel Clamp for the 3 bar system is designed to accept any of the Syrris Jacketed Vessel (rated […]

View module details -

Atlas Safety Enclosure (3 bar)

The safety enclosures for the Atlas 3 Bar Pressure System offers a compact and safe shield when pressurizing vessels and […]

View module details -

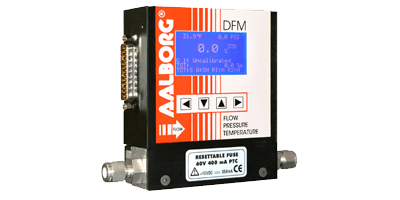

Aalborg Mass Flow Controllers

The Aalborg Mass Flow Controller is for use with Atlas Pressure Systems. It is ideal for applications such as dosing […]

View module details -

Aalborg Mass Flow Meter

The Aalborg Mass Flow Meters are for use with Atlas Pressure Systems. They are ideal for applications such as understanding […]

View module details -

Atlas PC Software 1

Atlas Software 1 is an easy-to-use PC based application for control and analysis of experiments. Whole systems including stirrers, circulators, […]

View module details

-

-

Circulation

-

Atlas Oil Drain Unit, Oil Pipe Tidy, and Oil Pipes

The perfect accessory for those wishing to change vessels with as little fuss and mess as possible. Atlas HD Oil […]

View module details -

Circulator and Fluid

Circulator options from industry-leading manufacturer, Huber. A range of circulator accessories and oils for whatever your application are available.

View module details

-

-

Dosing

-

Atlas Syringe Pump

View module details

-

-

Optional modules

-

Atlas PC Software 1

Atlas Software 1 is an easy-to-use PC based application for control and analysis of experiments. Whole systems including stirrers, circulators, […]

View module details -

Aalborg Mass Flow Controllers

The Aalborg Mass Flow Controller is for use with Atlas Pressure Systems. It is ideal for applications such as dosing […]

View module details -

Aalborg Mass Flow Meter

The Aalborg Mass Flow Meters are for use with Atlas Pressure Systems. They are ideal for applications such as understanding […]

View module details -

Atlas Syringe Pump

View module details -

Circulator and Fluid

Circulator options from industry-leading manufacturer, Huber. A range of circulator accessories and oils for whatever your application are available.

View module details

-

Support

These support articles may be helpful for this system

Contact us for more information

Do you have questions or need more details? Contact our expert team for more information on how the Atlas HD 3 Bar Pressure System can meet your specific needs.