Publication – Continuous flow synthesis of n-alkyl chlorides in a high-temperature microreactor environment

Organic Process Research & Development 2013, 17 (1), 152-157

- Benedikt Reichart, Guenter Tekautz, and C. Oliver Kappe

- Christian Doppler Laboratory for Microwave Chemistry (CDLMC) and Institute of Chemistry, Karl-Franzens University Graz, Heinrichstrasse 28, A-80010 Graz, Austria

- Microinnova Engineering GmbH, Reininghausstrasse 13a, 8020 Graz, Austria

This paper describes a continuous process for chlorination of alcohols. Originally optimised for microwave, the process was seamlessly transferred to an Asia flow chemistry system in order to scale up the reaction. By pressurizing a glass microreactor, the author was able to heat solvents above its boiling point like a microwave and achieve the chlorination with identical or even better yields.

This synthesis was performed using an Asia 110 system.

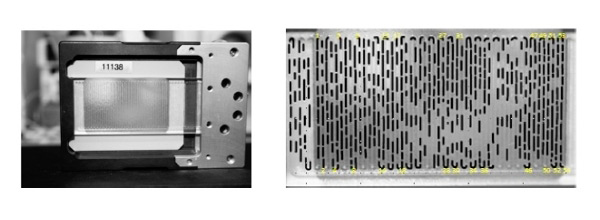

Abstract: Applying continuous flow processing in a high-temperature/high-pressure regime, n-alkyl chlorides can be prepared in high yields and selectivity by direct uncatalyzed chlorodehydroxylation of the corresponding n-alcohols with 30% aqueous hydrochloric acid. Optimum conditions for the preparation of n-butyl and n-hexyl chloride involve the use of a glass microreactor chip, a reaction temperature of 160−180 °C (20 bar backpressure) and a residence time of 15 min.

This paper uses an Asia 110 flow chemistry system and Asia Microreactors.